- Shaftless Spiral Conveyors

We have recently looked at the advantages of a shaftless screw conveyor over a traditional conveyor belt solution, but there is more equipment commonly used in materials handling facilities that can benefit from greater efficiency and reliability.

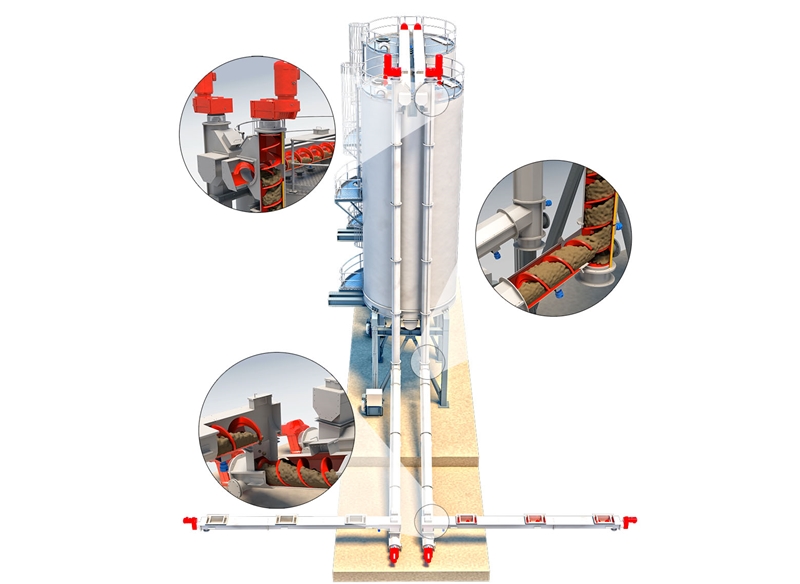

Designed for use in plants that regularly handle thick sludge, the cake pump has long been an option for transferring heavy, dewatered material. While the equipment is capable of getting the job done, a more effective solution is possible with the installation of shaftless spiral conveyors.

A question of reliability

In any materials handling plant, knowing that the equipment is going to run smoothly and without interruption is hugely important. Here is the key area that a shaftless spiral system has the advantage - offering unparalleled reliability. A cake pump runs at optimum efficiency when the moisture content of sludge is at a certain level, however issues with reliability make themselves apparent once those levels drop.

The shaftless screw conveyor from SPIRAC, on the other hand, maintains performance across a range of sludge moisture levels - it's even able to continue running dry. Part of the reason for that reliability comes from the comparatively simple mechanism - each conveyor involves just a single moving part per conveyor - simple to access, inspect and service.

Should there be a failure in the mechanism of a cake pump - perhaps a foreign object becoming jammed - the expense involved with repairing the equipment can be considerable. The open design and high torque of the shaftless spiral can reduce these types of incidents, with objects up to 90 per cent the size of the trough diameter easily passing through.

Flexibility of installation

While ensuring your system is reliable is of paramount concern, even the most fail-proof system will be of no use if you don't have the space to accommodate it. A cake pump may have the power you require when transferring sludge, but it comes with a heavy cost in terms of footprint, particularly in high pressure systems with a single discharge point.

SPIRAC's shaftless screw conveyors can be customised with multiple discharge points, and the sludge quality is largely unaffected throughout the process once a correctly designed system has been implemented.

For more information about how a shaftless screw conveyor may be a better solution for your facility, get in touch with the team at SPIRAC today.